Steel, metals in general, their various structures – are undoubtedly one of the favourite professional topics of conversation of the bridge designer Domas Čėsna. Having met a worthy specialist he will draw out anything, from a supply chain to the costs of human resources so that the final product would end up exactly where the designer intended and the costs would be kept at a minimum.

That’s what happened during the last competition “Lithuanian BIM Projects”, when at the end of June, in the meeting room of the Vilnius City Council – not via video conference, but finally live, without any masks! – the best projects developed in the digital environment in recent years were presented.

Head of the Bridge Department at “TEC Infrastructure” Domas Čėsna, together with the partners, presented a project of a viaduct over a railway in Mažeikiai, which has won the transport infrastructure prize at the already traditional competition organised by VšĮ “Skaitmeninė statyba” and the Lithuanian Constructors Association. The participants of the event held in the meeting room of the Vilnius City Council enjoyed the face-to-face communication as the period of strict quarantine was finally over and also became witnesses of a conversation on metal structures between two high level professionals – D. Čėsna and Director of “Projektai ir Co” Tomas Gudaitis.

Mažeikiai “turbo-roundabout”

If a viaduct of Mažeikiai would be built in any of the large cities of Lithuania, it would undoubtedly receive much more attention than it does now – both for its size and the complexity of the project, as well as for the applied innovative solutions, including the use of the common data environment. Certainly, this project will become a very good business card for “TEC Infrastructure” on the international infrastructure market.

The railway in Mažeikiai is of vital importance due to the oil refining factory, train traffic is intense. The city has long had two single-level crossings, so railway formations often paralyse the city. This issue will be solved by reconstructing one of the crossings to a two-level crossing.

The viaduct of 436 metres in length is rising at Algirdas street in Mažeikiai, and 4800 m3 of concrete, 440 t of steel and 520 piles were used in its construction. The total length of the engineering networks of each purpose is 3124 m. The whole infrastructure of this area will change: a nearby four-way junction will be reconstructed by constructing a turbo-roundabout at the junction of Algirdo and Gamyklos streets.

The viaduct should be completed this year. Project implementers: Lithuanian Road Administration and the Mažeikiai District Municipality. The contract works are carried out by the Latvian construction company “LNK Industries” together with “Eurovia Lietuva”.

Through BIM tools and the 3D element library…

The “TEC Infrastructure” team prepared the preliminary and the detail designs at the BIM environment. The company has been using BIM tools together with the parametrisation of objects for nearly five years.

“But even now we don’t always use 3D or BIM. We always consider, whether we need 3D or BIM – it’s also the human resources and whether digital technology will be used in the manufacturing process and if model control of the object will be performed during construction. However, all metal structures are designed straight on the 3D, – says D. Čėsna.

According to him, the engineers of “TEC Infrastructure“ historically use “Bentley” software when designing bridges – the first one was “MicroStation PowerDraft” for the development of 2D drawings, and currently we have “ProStructures”, “OpenBridge Modeler” and “ContextCapture”.

Domas Čėsna (on the left) and the head of the project part Aurimas Andzelis with nominations

Photo by Aleksas Jaunius

“TEC Infrastructure” is not the largest user of “Bentley” software products in Lithuania, but it undoubtedly uses them most effectively”, – says dr. Arūnas Urbšys, Director of Project Development at “IN RE, UAB.

“IN RE” innovations company operating in Vilnius since 1997 is an official representative of “Bentley Systems” for the Baltic States holding a “Bentley Gold Channel Partner” and an authorised training centre “Bentley Institute” status in Lithuania. The American company “Bentley Systems” operating globally, provides complex software solutions for the development and servicing of infrastructure.

Čėsna thoroughly describes the adaptability, advantages and drawbacks of each software package, which are rather subjective and determined by the fact ofhow the designers themselves have chosen a certain program for their everyday work.

He says: “OpenBridge Modeler” is intended for “macro” designing – to “drop” a bridge on the road and its main advantage is that it instantly provides the quantities. We have participated in a competition, where there were a lot of roads and many buildings; we spent a great deal of time, because we haven’t yet mastered the “OpenBridge Modeler”. We’ll be ready by autumn and waiting for the right project”.

In addition, “OpenBridge Modeler” has a continuously increasing BIM element library.

“The objects differ, but at the same time, they have similarities. We had three different bridge projects at once. We took on optimisation and we worked with them vertically, rather than horizontally. We grouped elements from all projects, which saved usa lot of time. This is how the element library accumulates, they’re easy to modify. For now, the adaptability of the models of the library is maybe only a fifth, but as the models increase, so will the adaptability, – says Domas Čėsna. Even in a very similar bridge there are different products, which must be individually adapted depending on the arrangement of reinforcements and other elements with respect to each other.

Speaking of another tool important to bridge builders “ProStructures”, which combines concrete with metal in a 3D model, the constructors at TEC don’t face any issues, however, a transition to “ProStructures CONNECT Edition” will have to be made from the 1st of January and the time lost due to quarantine will have to be compensated for.

The operational restrictions caused by the pandemic have so far prevented the proper use of “ContextCapture” program from “Bentley Systems” for creating photogrammetric reality models. However, as D. Čėsna puts it “we have seen good things, performed many continuous works, participated intraining sessions, and sought the quality that would please us. Now we just need to fully incorporate the software package into your daily routine.”

…to CDE

Contract works on the construction of the viaduct of Mažeikiai are carried out by the Latvian construction company “LNK Industries” which, among other things, has a large metal processing production capacity.

Seeing the potential of Latvians, D. Čėsna took to Riga, and, according to him, two cups of coffee was all it took, to agree on working in one model or in a common data environment for the implementation of this project.

The project clients were also offered to join so that they would be able to see in real-time how the project was implemented, but unfortunately… We’ll have to take another stop at the clients of the public sector.

Common Data Environment (CDE) is the only reliable source of project information intended to accumulate, process all relevant, verified project data in a consolidated way from the service supply chain and distributing it among all project teams. Though it was not used in this particular case, “Bentley Systems” offer one of the most powerful and popular engineering data and process management systems in the world – “ProjectWise”. It is used to create the general data environment for the “Rail Baltica” railway construction project.

SOLIDWORKS on the CDE plate

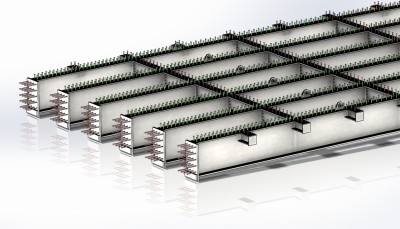

The metal elements of the Mažeikiai viaduct – both repetitive and variable – are innumerable. The programs used in the construction sector are no longer sufficient to develop them and control all the information about them, therefore, specialized parametric modelling tools used by the engineering industry are needed.

One of these programs is SOLIDWORKS.

When the discussion turns towards metals, Domas “turns on” again: “SOLIDWORKS are needed 100 percent when you design metal structures. I haven’t found a better program for metal than SOLIDWORKS. It’s a No. 1 program for modelling sheet steel. It is complemented by many free plug-ins, sometimes exotic ones. They save time. There was a case, when we completed the whole work in 4 hours using the appropriate SOLIDWORKS plug-in, instead of about a week. SOLIDWORKS ideally lines the geometry of two planes. Currently, no other program is capable of doing this.”

And adds – as if regretting, that, according to him, the “biggest advantage of SOLIDWORKS – assembly simulation, which we currently do not need”.

“SOLIDWORKS Corporation“established in the USA since 1993, since 1997 it is owned by a French Group “Dassault Systèmes”. Through many acquisitions, it has become one of the leading suppliers of 3D modelling, 3D simulations and Product Lifecycle Management (PLM) software in the world. “IN RE” company is a technical support and training centre in Lithuania authorised by “Dassault Systemes SOLIDWORKS Corporation”.

The viaduct of Mažeikiai is by far not the first project when the sub-contractor receives product 3D models designed in the SOLIDWORKS environment from TEC, but it’s the first time when this is done with CDE. It was through the CDE that Latvians were able to fulfil the order of Mažeikiai smoothly, on time and probably by saving nerves and costs.

Weekly program sift

On Fridays, the people from Bridge Department at “TEC Infrastructure” sift and mature programs, which are suitable / unsuitable for the work of the designers.

“You take a look at how much the program costs, where its return point is. You calculate your own return point and usually it does not correspond to the point of the program supplier. We then do an analysis of how you may be more attractive to the customer than other participants on the market. In what other ways can we create more added value for him? Where can we ourselves face issues and how to avoid them?”, – tells D. Čėsna.

According to him “the introduction of a program to the company’s turnover and for it to fully operate it actually takes 3 years. No trainings can speed that up – they will just make your way easier. Everything is determined by practice, practice and only practice”.

At the department, Friday is dedicated for the improvement of software package – “every employee draws up a plan on what he/she will be doing, what is a measurable result, what are we going to do next, if this doesn’t work out.”

When the times comes, Domas Čėsna, running his department for 4 years, and working at TEC for 14 years in total, makes a decision – is it suitable or not and what are we doing next.

For example, “Nemetschek Allplan “ program very popular in Germany was unsuitable: “We were constructing a bridge in Krekenava, maybe of 60 metres – everything works perfectly, the result is good, however, there was no return. We purchase it, but we do not purchase the support, because we see, that the Lithuanian market is not ready for this software package. There is a lack of critical mass of people, who would be using it.”

Huge challenges await the operation of transport infrastructure

“The client is not involved in the process of digitalisation”, – generalises D. Čėsna.

According to him, “engineering illiteracy has reached such a point, that there’s nowhere else to go. It cannot get any worse. The created technical tasks look good, on a letterhead, a few standards have been quoted, it’s written what to do, but from an engineering point of view certain issues are not solved like this. The practice of the actual competitions that took place, the issues of the design and construction of analogue buildings are not assessed. Design and construction is assessed, but the operation and maintenance are not”.

“Looking forward to the future – what will happen to the infrastructure in Lithuania in 15-20 years? The situation in the Lithuanian engineering world will be very sad, as there will be a lack of human resources working in operation and who would be able to manage the totality of information and strive for process improvement. For example, Lithuania will build “Rail Baltica”. The object is massive – and who is going to maintain it? The situation with the maintenance of infrastructure is already critical due to the lack of human resources and the lack of introduction of digital technologies. Without the training of specialists and the introduction of digitalisation, a collapse will follow”, – says the 37 year old engineer.

He also conveys this civic attitude and professional knowledge through lectures to his students at his Alma mater VGTU.

Prepared in collaboration with InRe®